Stunning bespoke kitchen done by TAG supplier Willoughby and Fahy

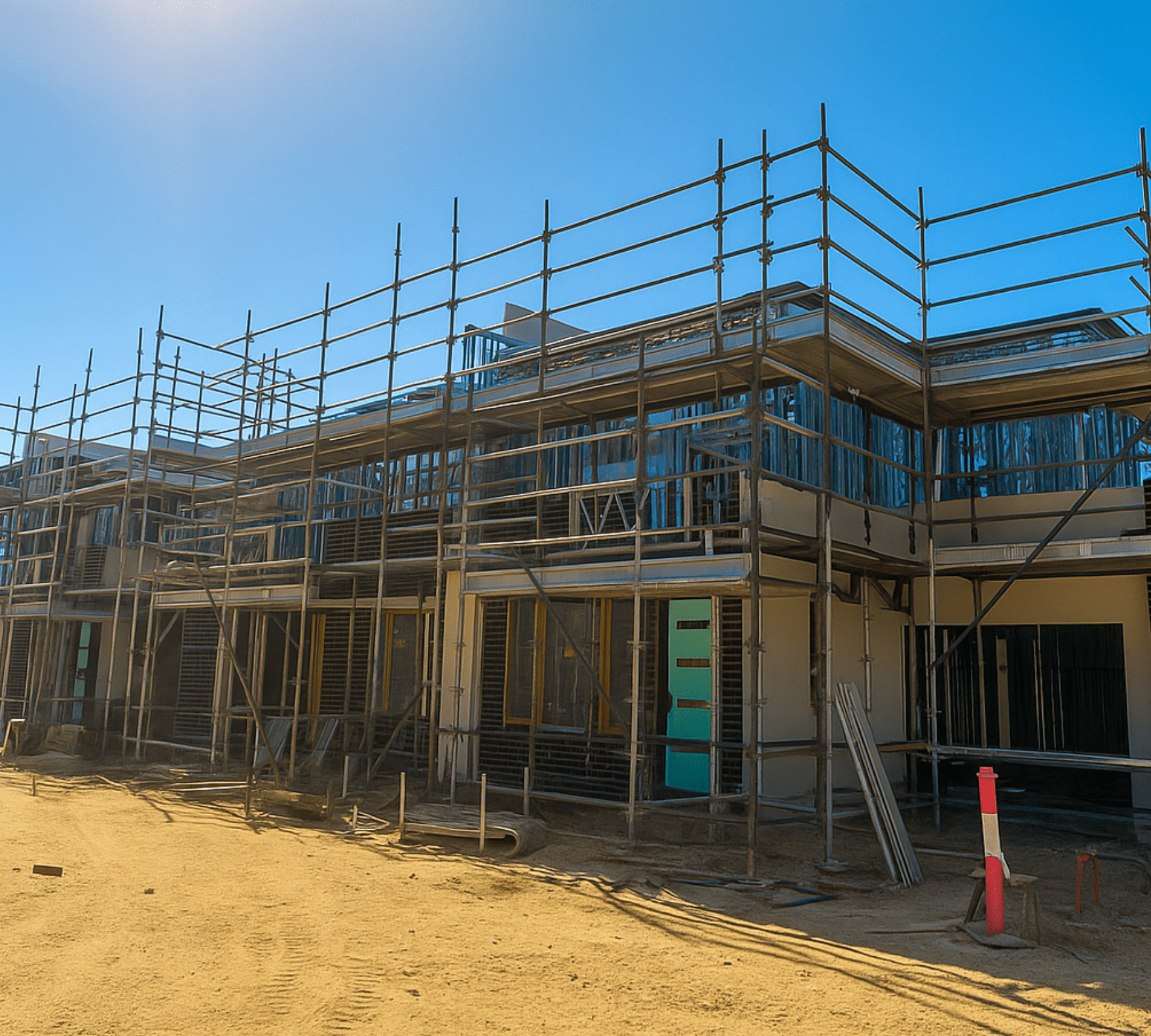

Many builders see scaffolding as something you “put in the quote and forget.” That mindset is risky. While scaffolders handle erection, as the builder or principal contractor you carry ongoing safety, coordination and legal liability from the moment that scaffolding is on site until it is dismantled. Victoria’s “Scaffolding Industry Standard,” published by WorkSafe and Foundations for Safety Victoria, emphasises that all parties have duties at every stage: design, construction, inspection, use, maintenance and dismantling. The standard is not stand-alone law, but it reflects best practice and is strongly referenced in enforcement. Failing to manage scaffold safety properly can lead to serious risks: scaffold collapse, falls from height, falling objects, interference with other trades.

If something goes wrong, whether a plank shifts, a guardrail’s removed, or another trade misuses the scaffold, WorkSafe won’t just look at the scaffolder. They’ll look at the builder who managed the site.

That’s why scaffold safety isn’t just about avoiding fines. It’s about keeping your crew safe, avoiding costly delays, and protecting your reputation.

What you can do as a builder to minimise risk

Get involved before the scaffold goes up

- Scaffold design should never be an afterthought. The National Construction Code and AS/NZS 4576 both recommend planning access and fall-prevention systems early in the build.

- Talk to your scaffolder during design or quoting, not a week before erection. A few quick sketches can reveal clearance or tie-in issues that might otherwise cost you time or a rebuild later.

- For complex façades or rooflines, insist on design drawings and load ratings before work begins. A good scaffolding company will provide these automatically, and Bay 2 Bay does exactly that.

Use licensed professionals and keep records

- Anything higher than four metres must be erected by a licensed scaffolder under the OHS Regulations (Vic). Builders must verify that every person putting up or altering the scaffold holds the correct licence and that their details are recorded on site.

- Keeping those records is not red tape. It is your evidence that you have taken “reasonably practicable steps” to meet your safety duty, which is what inspectors look for if an incident occurs. If your scaffolder cannot provide these details easily, it may be time to find a more reliable partner.

Do not skip handovers and scaffold tags

- Before trades use the scaffold, it must be inspected and tagged. The tag should show who inspected it, when, and the safe working load.

- The AS/NZS 1576 standards outline what those inspections must include, such as ties, guardrails, planks, access points, bracing and base conditions. Once the tag is in place, any change requires a new inspection. Builders who skip this process risk being accused of allowing unsafe work, and that is a costly reputation hit you do not need.

Maintain it once it is in use

- Scaffold checks do not end after handover. Builders must ensure scaffolds remain safe throughout the project, especially after strong winds or heavy rain.

- Under WorkSafe Victoria’s Scaffolding Industry Standard, builders should:

- Inspect weekly or after bad weather

- Prevent unauthorised changes by other trades

- Replace damaged planks or fittings immediately

- Keep clear access around scaffold bases

- A single collapsed bay can shut your site down for days, so regular inspections are always worth the time.

Coordinate with other trades

- Most scaffold issues happen after handover. Plumbers remove guardrails for flashing. Painters overload bays with tins. Bricklayers tie off where they should not.

- You cannot monitor every trade, but you can set clear expectations. Include scaffold care in toolbox talks, display signage on every level, and add scaffold conditions into subcontractor agreements.

- If a trade alters the scaffold without permission, require a fresh inspection before anyone else works on it. That simple step can prevent injuries, fines and project delays.

Dismantle it safely

- Dismantling can be just as risky as erection. Make sure your scaffolder provides a method statement and uses only licensed workers.

- Before clearing the area, check that the space below is isolated and that the scaffold is being removed from top down. Following the standard method keeps everyone safe and prevents damage to finished work.

Partner spotlight: Bay 2 Bay Scaffolding

Bay 2 Bay Scaffolding is a trusted Victorian scaffolding company that works with builders from concept to completion. Their team focuses on safety-first service, transparent communication, and practical scheduling that fits your build program.

They provide design drawings, load ratings, certified inspections, and ongoing maintenance to help builders meet compliance under Victorian regulations without stress.

Get your site off on the right foot and contact the responsive, safety-first team at Bay 2 Bay Scaffolding.

Mitigating site risks is easier when the scaffold is built and managed by people who understand your trade.